- KETAEBO Official

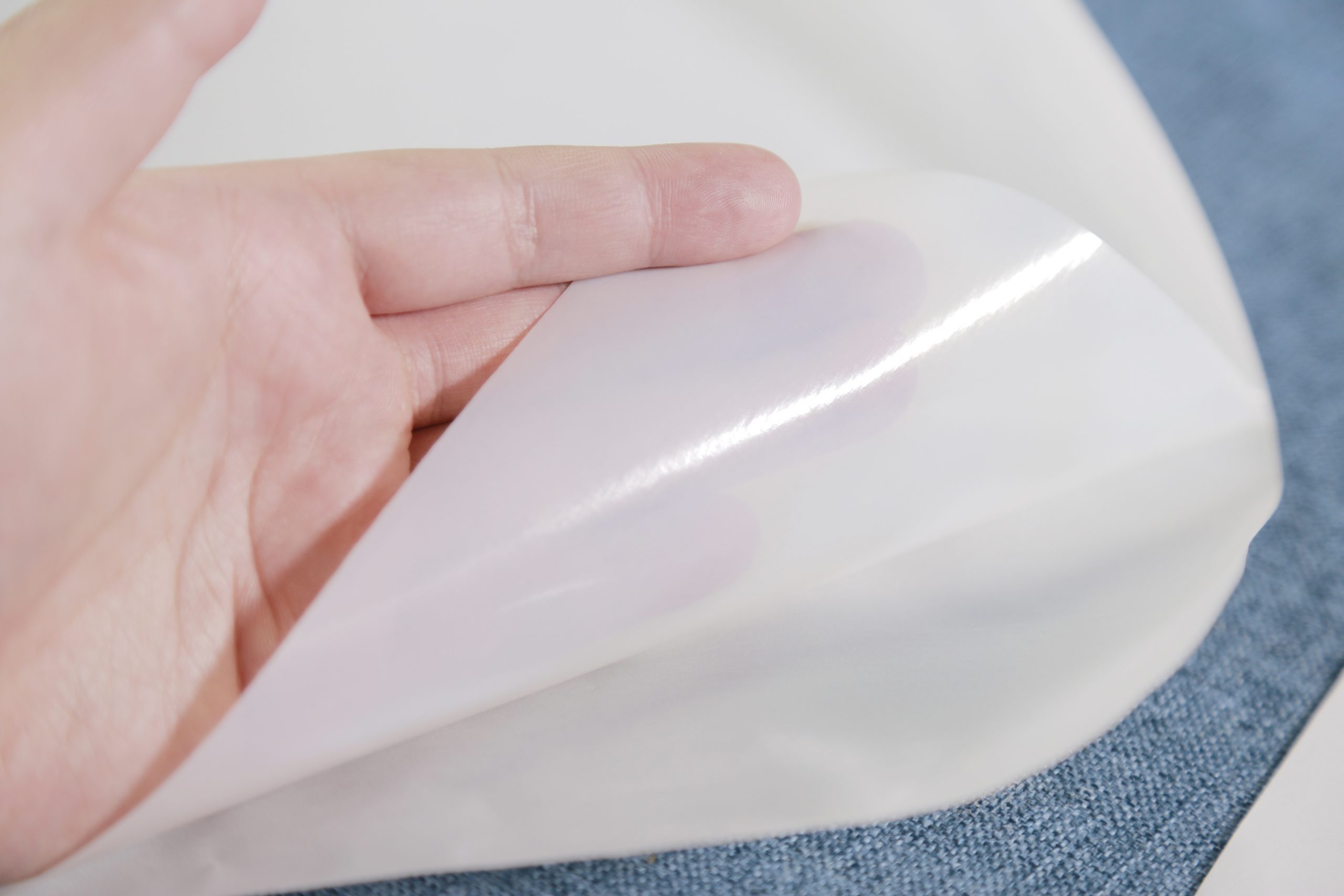

For textile fabric hot melt adhesive film and web

Different types of hot melt adhesive film and web should be used for different compositions of fabrics

To ensure the adhesion of the fabric, we need to use different types of hot melt adhesive films and webs. For example, cotton fabrics can use PA hot melt adhesive webs, while polyester fabrics can use PES or TPU hot melt adhesive films.

Hot melt adhesive film has higher bonding fastness, while hot melt adhesive web has air permeability and lower cost. For more differences between them, please refer to “The Difference Between Hot Melt Adhesive Film and Hot Melt Adhesive Web”.

It should be reminded that the composition and type of fabric are different concepts. We often hear terms such as cotton, polyester, oxford, and mesh. Among them, cotton and polyester refer to the composition of the fabric, while oxford and mesh only But it is a different weave type of fabric, and their composition may also be polyester. When we choose hot melt adhesive film, we consider the composition of the fabric rather than the type of fabric.

Bonding cotton or polyester-cotton blended textiles

It is recommended to use TPU hot-melt adhesive film and PA hot-melt adhesive web for the bonding of cotton or polyester-cotton fabrics. In fact, the viscosity of PA is better than that of TPU, but due to the high cost of PA and no elasticity, it is not suitable for hot melt adhesive film products. In the application, TPU hot melt adhesive film is more popular. In the hot melt adhesive web, the reason why the PA component is recommended is that the hot melt adhesive web itself is light in weight, and the viscosity should be considered as the primary condition.

Bonding polyester fiber textiles

TPU hot-melt adhesive film, PES hot-melt adhesive film, PO hot-melt adhesive film, PA hot-melt adhesive web and PES hot-melt adhesive web are recommended for textiles bonded with polyester components.

In the hot melt adhesive film, both PES and TPU have good adhesion to polyester fabric, PES has better washing resistance, and PO is slightly worse, but PO is cheap.

In the hot-melt mesh film, the viscosity of PA to polyester fabric is better than that of PES, but the washing resistance of PES mesh film is better.

Bonding polyester fiber textiles

Generally, only TPU hot melt adhesive film and hot melt adhesive web can be used for fabrics with spandex components. The reason is that the full name of TPU is polyurethane, and spandex is also polyurethane, so the stickiness between them will be better. And TPU hot melt adhesive film and web have elasticity.

If considering low temperature or low cost, EVA hot melt adhesive film and web film can also be applied, but their washing resistance and elasticity are not as good as TPU hot melt adhesive film and web film.

Bonding nylon fiber textiles

We recommend hot melt adhesive film and web adhesive with PA composition for fabrics with nylon composition because the full name of PA is co-polyamide, which is similar to polyamide with nylon composition. Hence, the viscosity of PA hot melt film is better than that of other compositions. Considering the high strength and washing resistance, TPU hot melt adhesive film can also be used.

Bonding PP non-woven fabric

Because PP non-woven fabrics are easily damaged by heat at high temperatures, only hot melt adhesive films and webs with low melting point can be used. Hot melt adhesives with EVA and low-temperature TPU components are recommended, and their pressing temperature is 80-110 ° C.

Precautions for choosing hot melt adhesive film and web

When choosing a hot melt adhesive film, in addition to considering the adhesion, you should also consider the feel of the fit, whether it has elasticity and the strength of washing resistance.

Consider the feel and elasticity

In hot melt adhesive films and web, EVA hot melt adhesive films and TPU hot melt adhesive films with medium and high-temperature melting points are elastic. Elastic products will feel relatively soft after lamination, so compared to For PA, PES, PO and low-temperature TPU hot melt adhesive films, it is more suitable to choose medium and high-temperature TPU and EVA hot melt adhesive films and web.

The second thing that affects the feel of the product after lamination is the thickness. For products under the same model, the smaller the gram weight and the thinner the hot melt adhesive film, the better the feel after lamination. But this also means that the fastness of the fit will be reduced because there is less glue per square meter.

Consider washable

The best wash-resistant hot melt film is TPU and PES, followed by PO, then PA, and finally EVA. However, the hot melt film with high lamination fastness also has better washing resistance, so the PA hot melt adhesive web is the most widely used in the bonding of textiles.

Other things to note

For the use of some customers, there will be other requirements for the hot melt film, such as high-temperature resistance, corrosion resistance, etc. It also needs to be considered and comprehensively selected.

FAQ

Different types of hot melt adhesive films and web raw materials have different prices, and the gram weight per square meter is also different; the lightest is 8 grams, and the heaviest is 240 grams. And some models of products are equipped with a layer of release paper, which will also increase the cost of the product. For specific prices, please refer to the product details page.

We support non-standard customization, including width, weight, length of each roll and other items, etc., please refer to the technical table, please contact us for details.

There are many reasons why the hot melt adhesive net is not firmly bonded, including the operation method, equipment condition and the selected hot melt adhesive net type. Among them, it is particularly important to choose different types of hot melt adhesive nets for bonding different materials, because each type of hot melt adhesive net has its own good bonding materials, which is not determined by its price. of. For example, when you plan to bond two kinds of EVA foam, it is more recommended to use EVA type hot melt adhesive web instead of TPU hot melt adhesive web, even if the price of TPU hot-melt adhesive web is more expensive. I suggest you click here for more details.

We can provide free samples to facilitate your testing. But we cannot bear the international logistics costs. It is best if you have a DHL, FedEx or TXT account.

We have a variety of packaging solutions. Usually, the packaging used for the entire roll is: PE bubble film + kraft paper woven bag, and the inner diameter of the paper tube is 76mm. If you need carton packaging and adding marks, please contact us.

Store in a dry place at room temperature and avoid direct sunlight. Theoretically speaking, the product has no shelf life limit, but it is not recommended to leave it for more than 18 months when it is not in use.

We support T/T, PayPal, Alipay, WeChat and other payment methods, and can provide FOB, EXW, CIF, DDU and other methods of quotation. The lead time varies according to the product model and quantity, usually between 3-30 days.

You can try to apply simple equipment, such as an iron or a flat ironing machine. If you need more professional and efficient equipment, I can recommend equipment manufacturers in China and provide technical support.

Yes, we can accept OEM, you can send us your requirements, and we will pack and label according to your requirements.

Hot melt adhesive webs are divided into many types and models according to their composition. They are different in terms of elasticity, color, washing resistance and suitable fields. They are divided into TPU hot melt adhesive web, PES hot-melt adhesive web, EVA Hot melt adhesive web, PA hot-melt adhesive web, etc. Among them, PA hot melt adhesive net is one of them. You can view more details by viewing an article on the classification of hot melt adhesive film types.

Yes, we can customize fusible webs and hemming webs, and we have relevant production experience, such as 45 cm width * 5 m length/roll and 43 cm width * 93 cm width/bag, etc. If you have a product sample like this, we can customize the finished product according to your sample and packaging design drawing. MOQ is 2000 units/model.

The PA hot melt adhesive net we produce is a thermoplastic hot-melt adhesive net. When it is exposed to high temperatures, it will repeatedly melt, not just once. Therefore, after you use it to make a product, you should not expose it to high temperatures again.

Hot melt adhesive web & net

Online Chat

Contact Detail

-

[email protected]

[email protected] - +86 18641000189

- 18641000189

- +86 18641000189

- 825900650

- No. 48, Development East Road, Wanping Community, Wujiang District, Suzhou City, Jiangsu Province, China