Hot melt adhesive bonding web

Different Types of Hot Melt Adhesive webs

PA hot melt adhesive web is the most used one in hot melt adhesive web. It can be washed with water, has very good dry cleaning resistance, and has no elasticity. It has good adhesion to all kinds of fabrics and leather, is widely used in the field of clothing and home textiles, and is also favored by handicraft enthusiasts. PA hot melt adhesive web has two melting points, 98-110 ℃, and 115-125 ℃ respectively.

Advantages: suitable for all kinds of fabrics, leather, good stickiness, excellent dry cleaning resistance

PES hot melt adhesive web has excellent washing resistance and no elasticity. It has good viscosity to polyester fabric, PET film, polyester sponge, and other materials. The melting point of the PES hot melt adhesive web is about 110°C, and the recommended pressing temperature is about 135-160°C.

Advantages: Excellent washability

EVA hot-melt web has good elasticity and softness but is slightly less sticky to textiles and washable. It can be used to bond PP non-woven fabric, XPE foam, EVA foam, etc. The melting point is low, only about 65°C, and the recommended pressing temperature is around 80-110°C.

Advantages: Elasticity, softness, low temperature fit

TPU hot melt adhesive web has a high melting point (TWU98) and a low melting point (TWU68). It has good viscosity to spandex fabric, leather, and polyurethane sponge, and has excellent washing resistance. Among them, TWU98 has elasticity, soft to the touch after lamination, and the melting point is about 115℃; TWU68 has no elasticity, and the melting point is about 65℃.

Advantages: TWU98-soft, washable;TWU68-low temperature fit, washable

What is a hot melt adhesive web?

Hot melt adhesive web, also known as double-sided fusible interfacing, is a thermoplastic hot melt adhesive that has no viscosity at room temperature, melts at high temperature, and is viscous on both sides. It is a kind of adhesive. Non-woven fabrics are very similar. It has many names, including bonding web, fusible web, double-sided iron on interfacing, iron on fusing web, etc.

Hot melt adhesive web with and without backing paper

The hot melt adhesive web is usually without release paper, and it is directly placed between the two layers of materials that need to be bonded, and if you want it to have a layer of release paper, it can also be customized, and the width can be customized. The width is usually 1120mm. And if you want to customize 1500mm width, you need at least 20,000 meters of MOQ. We can also cut it narrow, such as 1cm, 1.5cm, 2cm, 2.5cm, etc.

Gram weight of hot melt adhesive web

There are many gram weights of hot melt adhesive web, the minimum is 8g, and there are 10g 12g 15g 18g 20g 23g 25g 30g 40g 50g 60g 90g, etc., different types of hot melt adhesive web The customizable gram weight range is also different. Usually, 8-18g belongs to light and thin hot melt adhesive web, 20-35g belongs to medium gram weight hot melt adhesive web, and 40g or more belongs to heavy hot melt adhesive web.

Color of hot melt adhesive web

The color of the hot melt adhesive web is usually white, if you need other colors, we can customize them, but there will be MOQ and other charges. In addition to white, we also have the XWA116 model in black, its model number is TWA120H, you can check this link.

About the width and the length of each roll

width:

The most commonly used width in hot melt adhesive web is 1500mm. Of course, the width can be customized, from 5mm-3150mm.

Hint: 1000 mm=100 cm=1 meter.

Length of each roll:

The most commonly used length per roll is 500 meters per roll. Some specifications with higher gram weights will have fewer meters per roll. For example, 40 grams is usually 300 meters or 200 meters per roll. Of course, the number of meters per roll can be customized. For example, some of our customers require us to make 12 grams into 1500 meters/roll, and some customers need us to make 100 meters or 100 yards per roll.

Hint: 100 yards = 91 meters.

Fields of application of hot melt web and suitable materials for bonding

Hot melt adhesive web is mainly suitable for the bonding of fabrics and can also be used for the bonding of materials such as sponges and leather. Its main application areas are clothing, shoes and hats, automotive interiors and home textiles. Like many people searching for double-sided fusible interfacing, it is used for clothing.

It should be noted that different types of hot melt adhesive webs are suitable for different materials and application fields. For example, the XWA116 model is more used in clothing because it has good fastness to many kinds of fabrics, it is resistant to washing and dry cleaning, and has a high-cost performance; and if it is to bond leather, many customers will choose XWA95, because it can provide higher fastness and lower melting point; when bonding XPE foam, many people choose EVA hot melt adhesive web because it has better viscosity and lower melting point. You can click on the links above to learn about these products or send us an email with the materials you plan to bond, and we will recommend suitable products for you.

Reference article “Hot melt adhesive film and web for textile fabrics“

How to use the adhesive web:

Hot melt adhesive webs are available in different thicknesses, widths and lengths per roll, and the range of specifications customized for each model is also different. You can obtain this information by viewing the product links above.

Without backing paper:

1. Cut the product into a specific shape according to your needs or use it directly.

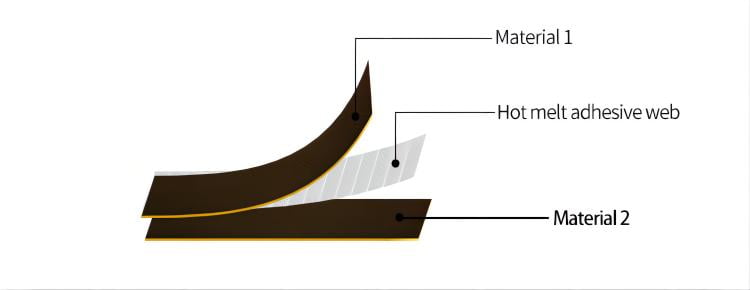

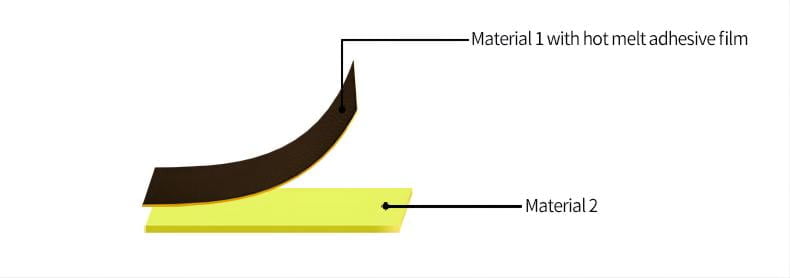

2. Place the hot-melt adhesive web between the two layers of materials that need to be bonded. The order of placement is material 1/hot-melt web/material 2.

3. Use an iron or professional pressing equipment to heat and iron on material 1 or material 2 sides (choose the material on the side that is easy to heat). Conduct heat to the hot-melt web in the middle and melt it to bond with material 1 and material 2 to complete the bonding.

Example: Plan view of double-layer material bonding:

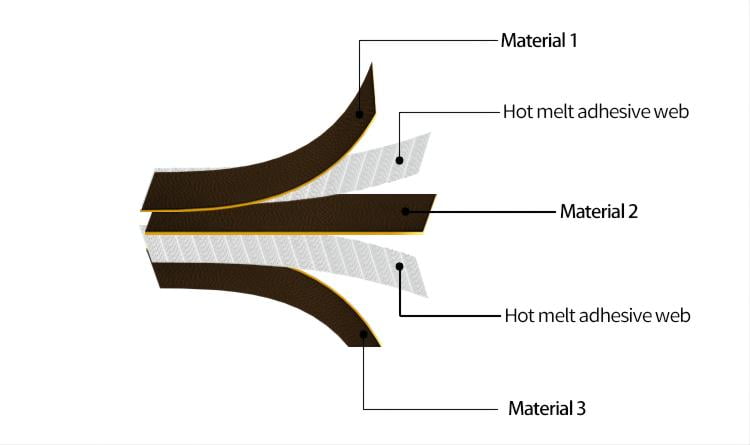

Example: Plan view of three-layer material bonding:

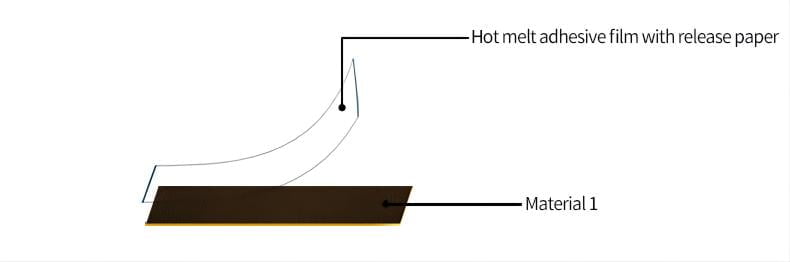

With backing paper :

1. Place the adhesive side of the hot melt adhesive web with the material to be bonded, with the release paper side facing up, and the order of placement is: release paper layer/adhesive film layer/material to be bonded1.

2. Use a relatively low temperature to heat the release paper side to make it adhere.

3. After cooling, peel off the release paper.

4. Align the glued material 1 with the material on the other side (material 2) that needs to be bonded. The placement sequence is material 1 / hot melt adhesive layer/material 2, and then use ironing equipment to bond. That is, the bonding industry is completed.

First bonding:

Second bonding:

About properties:

Washing, dry cleaning

The order of hot melt adhesive web from strong to weak is: PES hot melt adhesive web, TPU, PA, EVA, among which PES has the best washing resistance effect and EVA has the worst washing resistance effect. However, one thing to note is that if you plan to use it in clothing, we recommend using PA hot melt adhesive, because it has good fastness, which can make up for its shortcomings in this regard. In manual work, PA Hot melt adhesive web is also the most popular. On dry cleaning, PA hot melt web is the best because it is chemically stable at high temperatures and will not delaminate or fail.

Elasticity

In the hot-melt adhesive web, the hot-melt adhesive web film of PA and PES and low-melting-point TPU components has no elasticity, while EVA and high-melting-point TPU are elastic.

softness

The softness and hardness of the hot melt adhesive web depend on two aspects one is elasticity, and the other is gram weight. If the hot melt adhesive web has elasticity, such as the LWV65 and TWU98 models, it will feel softer after it is attached, while if the adhesive web has no elasticity, it will feel stiff. In terms of gram weight, the lighter the weight, the better the feel, and the higher the weight, the harder the feel. But it should be noted that light weight also means that its bonding fastness is relatively poor.

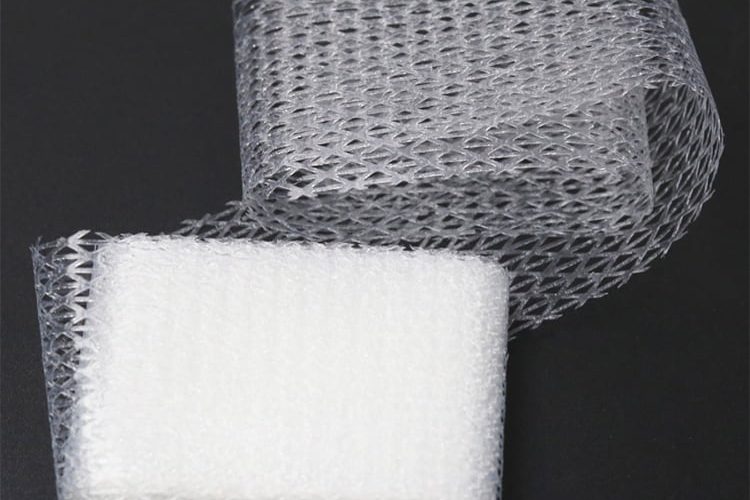

Appearance and structure

Hot melt adhesive b has net shape (with backing paper, 35gms) and grid shape (without backing paper, 28gms) in addition to non-woven shapes, as shown in the figure below, they are all CO-PA components, if This is the product you want, you can click the link below to view it.

Related Products - Hot Melt Adhesive film:

Hot melt adhesive web can not meet the needs of some people. If you think it is too thin, consider using hot melt adhesive film products, as shown in the figure below. The hot-melt adhesive film is similar to the hot-melt adhesive web. Both use hot-melt adhesive as raw material, and they are both sticky on both sides, but we make it into a film shape. Its advantage is that it has better viscosity and the whole surface is full of Adhesive, and there are two types with backing paper and without backing paper.

Better tack and wash resistance, optional with or without release paper

Related Products - iron on adhesive paper and fusible bonding web

If you are a wholesaler of handmade enthusiast supplies, then we can undertake OEM/ODM processing of fusible web. We can customize its size and packaging according to your needs, we have cooperated with some manufacturers and have relevant experience, our main advantage is that the hot melt adhesive web and film are produced by ourselves, so the price is more Advantage. Click the link below to read more about this.

If you need the product in the picture, you can click here to view it.

If you need the product in the picture, you can click here to view it.

Projects we undertake:

We mainly sell hot melt adhesive web products; you can buy them directly. At the same time, we also undertake the back glue and lamination processing business of hot melt adhesive web. If the fabrics and leathers you purchased in China need to be back glued or laminated, you can ship these goods to our factory, and we use professional laminating equipment to attach the hot melt adhesive web products to the fabrics you provide.

FAQ:

The hot-melt adhesive web is the same as a hot-melt glue stick. They are all 100% hot-melt adhesive products, without the ingredients of fabrics. They are sticky on both sides at high temperatures and are used for compounding two kinds of fabrics; while the adhesive interlining is used on One side of the fabric is made of dotted hot melt adhesive. One side is the fabric and the other side is the dotted hot melt adhesive. Therefore, it is usually bonded on one side at high temperatures. The main function is to stick to one side of the fabric. Makes the fabric stiffer.

We support non-standard customization, including Gram weight, thickness, length of each roll and other items, etc., please refer to the technical table, please contact us for details.

There are many reasons why the hot melt adhesive web is not firmly bonded, including the operation method, equipment condition and the selected hot melt adhesive web type. Among them, it is particularly important to choose different types of hot melt adhesive web for bonding different materials, because each type of hot melt adhesive web has its own good bonding materials, which is not determined by its price. of. For example, when you plan to bond two kinds of EVA foam, it is more recommended to use EVA type hot melt adhesive web instead of TPU hot melt adhesive web, even if the price of TPU hot melt adhesive web is more expensive.I suggest you click here for more details.

We can provide free samples to facilitate your testing. But we cannot bear the international logistics costs. It is best if you have a DHL, FedEx or TXT account.

We have a variety of packaging solutions. Usually, the packaging used for the entire roll is: PE bubble film + kraft paper woven bag, and the inner diameter of the paper tube is 76mm. If you need carton packaging and adding marks, please contact us.

Store in a dry place at room temperature and avoid direct sunlight. Theoretically speaking, the product has no shelf life limit, but it is not recommended to leave it for more than 18 months when it is not in use.

We support T/T, PayPal, Alipay, WeChat and other payment methods, and can provide FOB, EXW, CIF, DDU and other methods of quotation. The lead time varies according to the product model and quantity, usually between 3-30 days.

You can try to apply simple equipment, such as an iron or a flat ironing machine. If you need more professional and efficient equipment, I can recommend equipment manufacturers in China and provide technical support.

Yes, we can accept OEM, you can send us your requirements, and we will pack and label according to your requirements.

Yes, we can customize fusible webs and hemming webs, and we have relevant production experience, such as 45 cm width * 5 m length/roll and 43 cm width * 93 cm width/bag, etc. If you have a product sample like this, we can customize the finished product according to your sample and packaging design drawing. MOQ is 2000 units/model.

The hot melt adhesive web we produce is a thermoplastic hot-melt adhesive film. When it is exposed to high temperatures, it will melt repeatedly, not just once. Therefore, after you use it to make a product, you should not expose it to high temperatures again.