- KETAEBO Official

For waterproof socks gloves PU waterproof breathable membrane with double-sided hot melt adhesive dots

Brand: KETAEBO

Certification : SGS Phthalate Testing

Model: TU1513, DU1513, JU1513

Place of Origin: China

MOQ: 100 Pairs

Delivery time: 3-10 days

Payment Terms: T/T, Western Union, Paypal

Supply: 9000 Pairs per day

Product Introduction

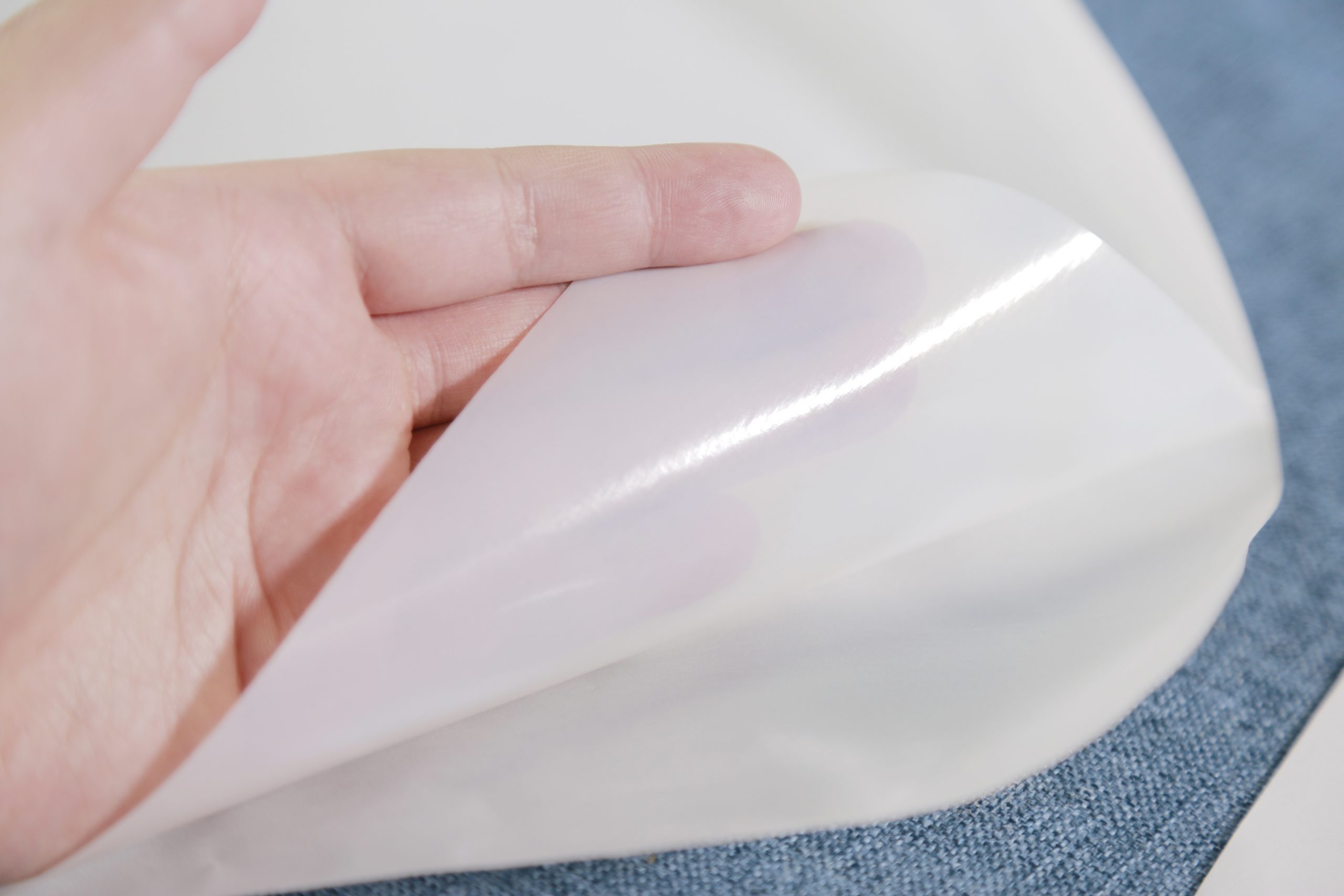

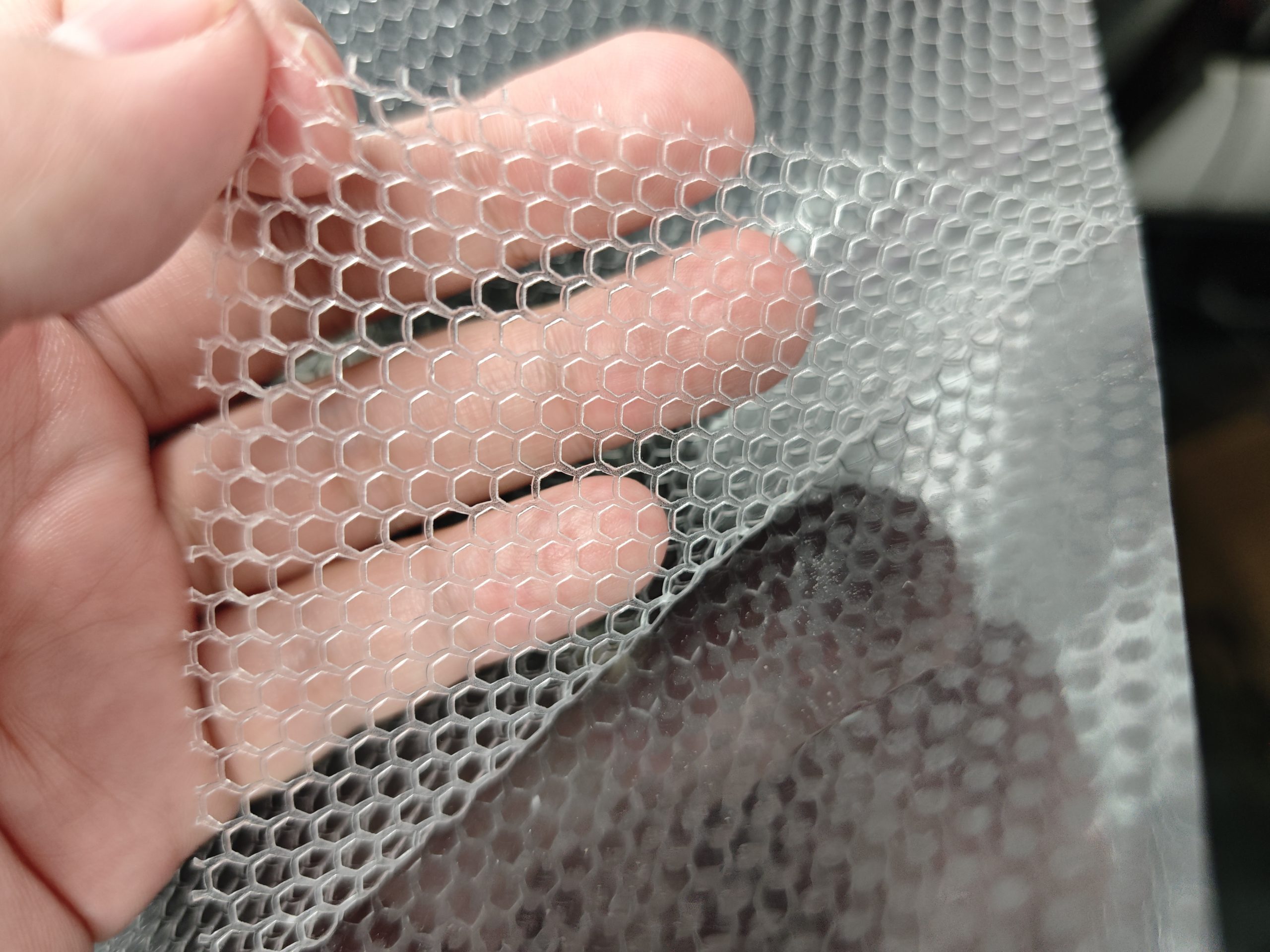

The PU waterproof membrane with hot-melt adhesive dots on both sides is a waterproof and breathable film material. It is a product made by coating hot-melt adhesive dots on both sides of the PU or TPU film. It can be customized into the shape of gloves, socks or hats according to customer needs, and placed between the inner and outer fabrics to make waterproof gloves and waterproof socks.

Hot melt adhesive is an environmentally friendly adhesive that is not sticky at room temperature but melts and becomes sticky at high temperature (150℃). It is harmless to the human body, so you can safely use it in gloves or socks. When using this product, you need to use thermal bonding equipment, such as a flat-bed heat press machine or similar principle equipment. Because hot melt adhesive exists in the form of dots, it has little effect on the moisture permeability and soft and hard feel of the film.

Applicable fields:

- Waterproof socks

- Waterproof gloves

- Ski gloves

- Windproof hat

- Waterproof shoes

- Outdoor Jackets

Characteristic:

- water proof

- Moisture permeable

- Micro elasticity

- Double-sided with hot glue dots

- Shapes can be customized according to requirements

We have three types of waterproof membranes with hot melt adhesive, namely TU1513, DU1513 and JU1513, which are ranked from high to low in terms of moisture permeability: JU1513, DU1513, TU1513. Among them, TU1513 has the lowest cost and the waterproof membrane is made of TPU material.

Technical Data Sheet

| Model | TU1513 | DU1513 | JU1513 | |

|---|---|---|---|---|

| Weight (g/sqm) (ISO 2286-2) | ||||

| Total weight | 56 | 56 | 56 | |

| Membrane weight | 30 | 30 | 30 | |

| Hot melt adhesive weight | 26 | 26 | 26 | |

| Membrane thickness(mm) | 0.022-0.028 | 0.022-0.028 | 0.022-0.028 | |

| Colour | Transparent | Matte | Matte | |

| Membrane Type | TPU | PU | Hydrophilic PU | |

| Temperature resistance of the membrane | >180℃ | >180℃ | >180℃ | |

| Breathability (g/sqm/24hr) | ||||

| ASTM E96: 95 Procedure B | - | - | 600 | |

| ASTM E96: 95 Procedure BW | - | - | 16,200 | |

| JIS L 1099 A1 | - | - | >3,000 | |

| JIS L 1099 B1 | - | - | >15,000 | |

| Waterproofness(mm) | ||||

| JIS L 1092 B (modified*) | - | - | >20,000# | |

| JIS L 1092 A (modified*) | - | - | >10,000 | |

| Melting point of hot melt adhesive(℃) | 125 | 125 | 125 | |

| Hot melt adhesive composition | TPU(Polyurethane) | TPU(Polyurethane) | TPU(Polyurethane) | |

| Recommended use parameters | Use temperature(℃) | 145-160 | 145-160 | 145-160 |

| Ironing pressure(MPa) | 0.15-0.2 | 0.15-0.2 | 0.15-0.2 | |

| Ironing time(s) | 15-25 | 15-25 | 15-25 | |

| Characteristic | Slightly elastic, smooth | Slightly elastic, high moisture permeability | Slightly elastic, high moisture permeability, better film toughness | |

The different models of PU waterproof breathable membrane with double-sided hot melt adhesive dots

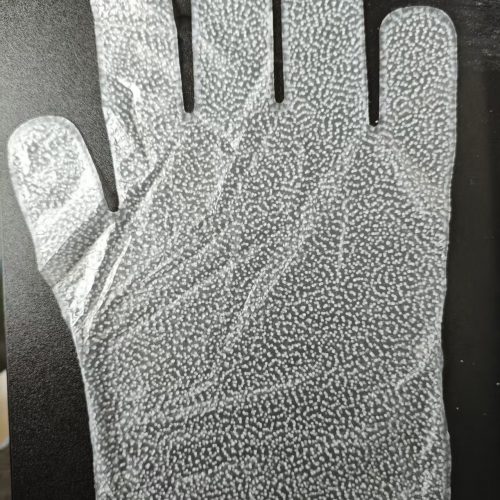

TU1513 TPU membrane with adhesive dots

Common weight: 56gms

Common width: 1520mm

The common length of every roll:500 meters/roll

Characteristic: Slightly elastic, smooth

DU1513 PU membrane with adhesive dots

Common weight: 56gms

Common width: 1520mm

The common length of every roll:500 meters/roll

Characteristic: Slightly elastic, high moisture permeability

JU1513 PU membrane with adhesive dots

Common weight: 56gms

Common width: 1520mm

The common length of every roll:500 meters/roll

Characteristic: Slightly elastic, high moisture permeability, better film toughness

Related products

If you need the product in the picture, you can click here to view it.

We can sell it by the yard or make it into a specific shape.

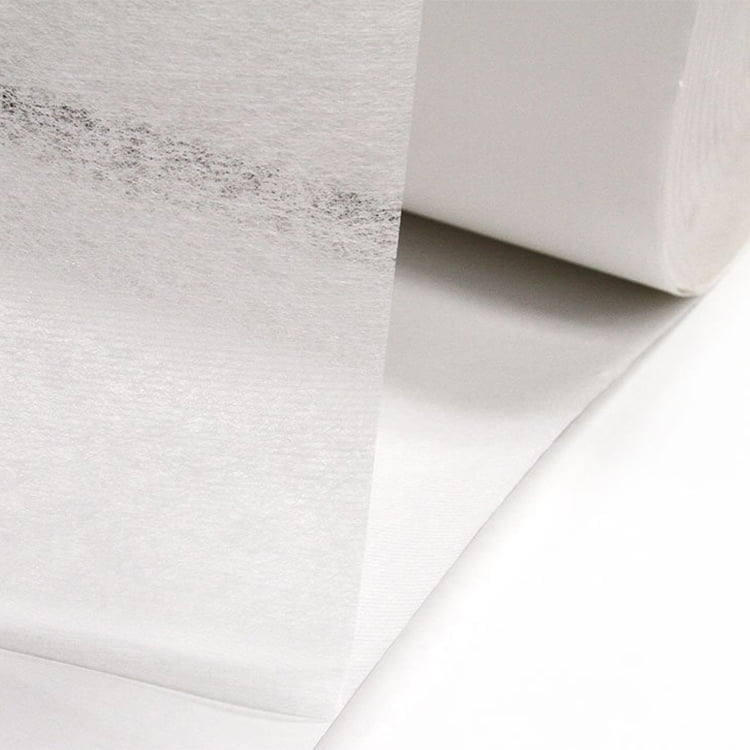

The waterproof and breathable membrane with hot melt adhesive is 1500mm wide when it leaves the factory. We can sell it by yard or by meter, usually each roll is 200-500 meters long. At the same time, we can also make it into a special shape according to customer needs, such as gloves, socks, hats or other shapes.

Our advantage

Source manufacturer, providing wholesale sales

We are a manufacturer of PU membrane with adhesive dots in China, not a trader, you can get more favorable wholesale prices. We have multiple production equipments with a daily output of 10,000 meters.

Made of 100% hot melt adhesive particles

The hot melt adhesive dots we produce are made of 100% hot melt adhesive particles, and no other materials (such as talcum powder) are added to ensure better bonding performance and quality of the product.

Has passed SGS's RoHS 2.0 test

The product has passed SGS's RoHS 2.0 test. It is safe and has no harm to the body. It can be exported to Europe, America and other countries.

FAQ

There is no accurate data for TU1513 and DU1513 because they have not been specifically tested. According to the data provided by the film supplier, the moisture permeability of TU1513 is about 3000, while that of DU1513 can reach 12000, and that of JU1513 is 20000.

Yes, you need to send us the final shape drawing, and we will calculate the price, including product price, mold price, etc. Usually there is no minimum order quantity, but the product price will be higher when the quantity is small. And the mold fee can be returned to the buyer or deducted from the future payment, but it needs to meet a certain payment amount.

TPU/PU waterproof and breathable membrane is not breathable and can only pass a certain amount of water vapor. Therefore, we usually do not talk about waterproof and breathable membranes, but waterproof and moisture-permeable membranes. The data is also based on the water vapor permeability within a certain period of time.

We can provide free samples to facilitate your testing. But we cannot bear the international logistics costs. It is best if you have a DHL, FedEx or TXT account.

When we sell by the yard, because it is a coil, we usually pack it in woven bags for delivery; if it is a special shape, we will pack it in cartons for delivery.

Store in a dry place at room temperature and avoid direct sunlight. Theoretically speaking, the product has no shelf life limit, but it is not recommended to leave it for more than 18 months when it is not in use.

We support T/T, PayPal, Alipay, WeChat and other payment methods, and can provide FOB, EXW, CIF, DDU and other methods of quotation. The lead time varies according to the product model and quantity, usually between 3-30 days.

This is because the products produced need to have good stretchability. Take socks as an example. If my shape is made the same size as the actual socks, because the film is not like fabric and does not have particularly strong elasticity, when the customer wears the socks, the film is likely to be torn and the product will be damaged. Therefore, it needs to be made very large. However, due to problems with the production process during production, the final product is not much different from regular socks and does not appear to be very large.

Take socks as an example. You need to make a metal mold of similar size according to the drawing. It is flat. Then put the inner fabric, waterproof membrane and outer fabric of the socks into the mold in turn. At this time, the socks are stretched very large. Then heat press the front and back to make the glue points on the film melt and bond the inner and outer sock fabrics together. Then take it off the mold for water leakage detection. The passed product is wet at this time. Put it into a mold of the actual size of the socks and bake it in the drying room. The product returns to its original shape.

Yes, compared to PU film, TPU film is smoother, which makes it easier to be put into the mold and less likely to be damaged by friction.

Yes, but the impact is not significant. Of course, we can also make the spacing between the hot melt glue points larger, so that the impact on moisture permeability will be smaller.

TU1513 has the lowest cost, followed by DU1513, and the highest is JU1513. Of course, in terms of moisture permeability, JU1513 also has the best performance. TU1513 is a TPU waterproof and breathable membrane, while JU1513 and DU1513 are both PU waterproof and breathable membranes.Although TU1513 has the lowest cost, DU1513 is the best in terms of cost performance.

PU waterproof and breathable membrane is hydrophilic, while TPU is water-repellent. That is to say, DU1513 and JU1513 are hydrophilic, while TU1513 is not. Therefore, compared with TU1513, DU1513 and JU1513 have better breathability and are more comfortable to wear when made into gloves and socks.

Online Chat

Contact Detail

-

[email protected]

[email protected] - +86 18641000189

- 18641000189

- +86 18641000189

- 825900650

- No. 48, Development East Road, Wanping Community, Wujiang District, Suzhou City, Jiangsu Province, China